Crafting Quality Fasteners with Precision

Manufacturing & Quality Solutions

At PRK Technologies GmbH, we are dedicated to delivering precision-engineered fasteners that meet the highest European quality standards. Our state-of-the-art manufacturing facilities, operated by skilled professionals, utilize cutting-edge technology to ensure each product is crafted with meticulous attention to detail. From design to production, we uphold rigorous quality control measures to guarantee the integrity and reliability of our fasteners.

Quality assurance is at the core of our operations. We source our materials from internationally renowned and certified manufacturers, ensuring that our products meet or exceed national and international standards. With PRK Technologies, you can trust in the excellence and durability of our fastening solutions.

Quality assurance is at the core of our operations. We source our materials from internationally renowned and certified manufacturer, ensuring that our products meet or exceed national and international standards. With PRK Technologies, you can trust in the excellence and durability of our fastening solutions.

Precision Sourcing and Distribution, Unmatched Quality – Trust PRK Technologies for Reliable Fastening Solutions

Testing Facilities

Advanced testing facilities at MPS guarantee the highest standards of quality and performance for every product. Utilizing state-of-the-art equipment, Our Manufacturer rigorously tests fasteners to ensure they meet stringent industry specifications and exceed customer expectations.

- Hardness Testing (HRB, HRC, HV Scales)

- Yield Stress

- Proof Stress

- Ultimate Tensile Strength

- Elongation Percentage

- Bend Test

- Metallurgical Testing

- De-Carb Testing

- Micro-Structure

- Inclusion Rating

- Crack Detection

- Roughness Testing (Ra, Ry, Rz)

- Torque Testing

- Coating Thickness Testing

- Salt Spray Test

- HCL Testing

- Specific Gravity

- Concentration of HCL

- Spectrometer- For Chemical Composition

- CMM for critical dimensions

Facilities & Products

Advanced Plating and Heat Treatment

Tool Room and Custom Solutions

Inspection

- Well Defined CTQ and CTP

- Measurement for CTQ and CTP

- Detailed FMEA with RPN

Quality Control

- PDI Inspection

- Stage /Subsequent Inspection /Quality Gate Inspection

- Petrol Inspection / Testing

- Red Bin Analysis , 5-Why Analysis, CAPA / 8D Analysis

- Poka-Yoke

Quality Audit

- Countermeasure Adherence Audit

- Poka-Yoke Audit

- SOP vs Actual Work

- 4M Change management audits

- Dock Audit/ 100 % Traceability

Quality Assurance

- Supplier Quality Assurance

- Product and Process Quality Assurance

- New Product Quality Assurance

- People Development – Quality Mindset – COPQ Approach

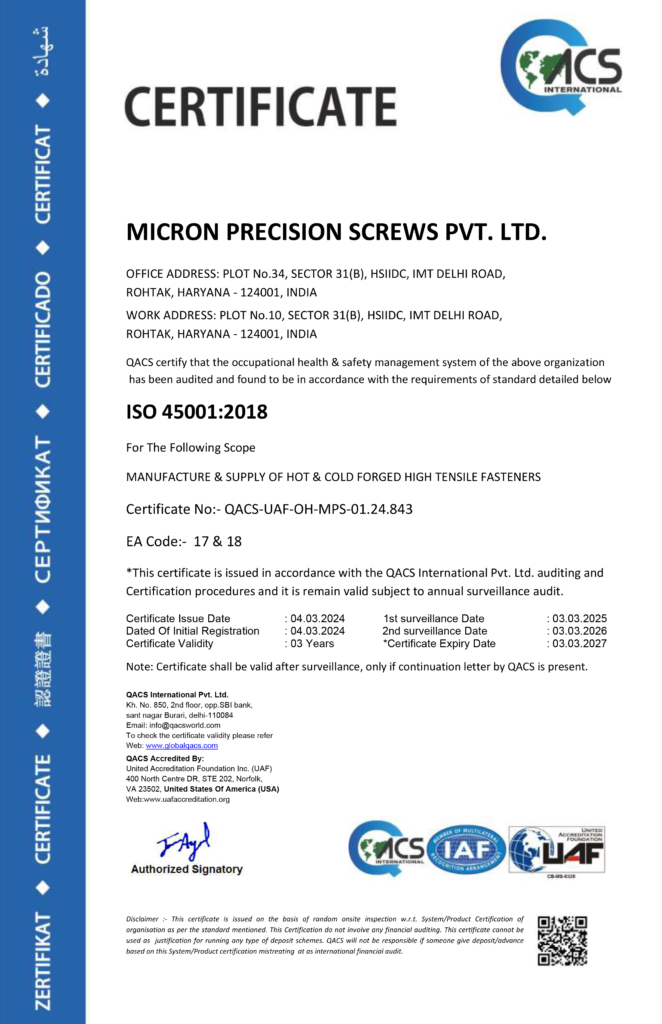

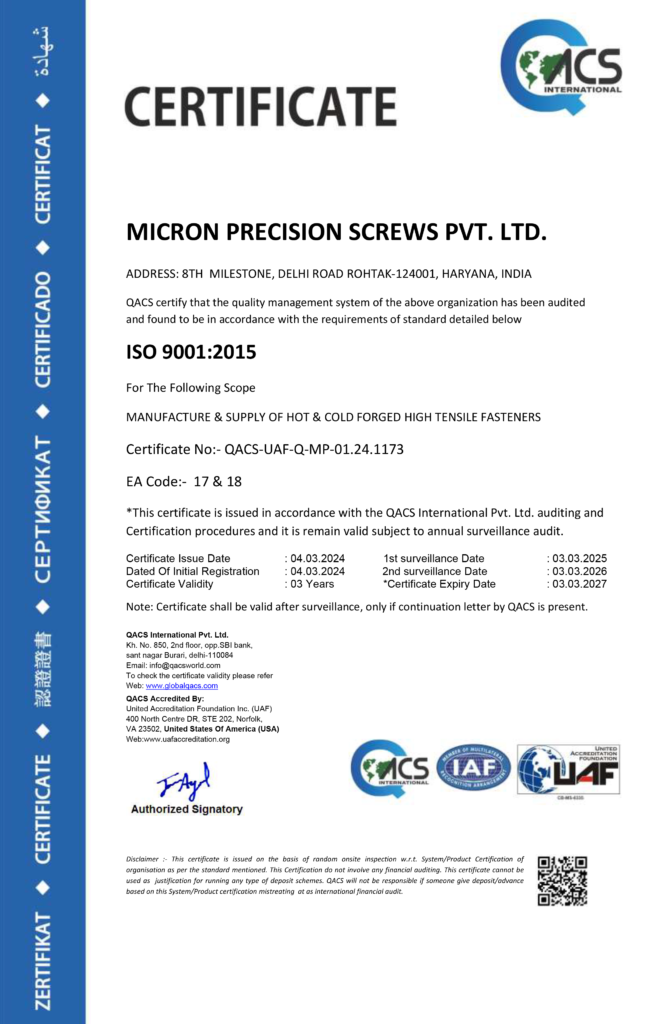

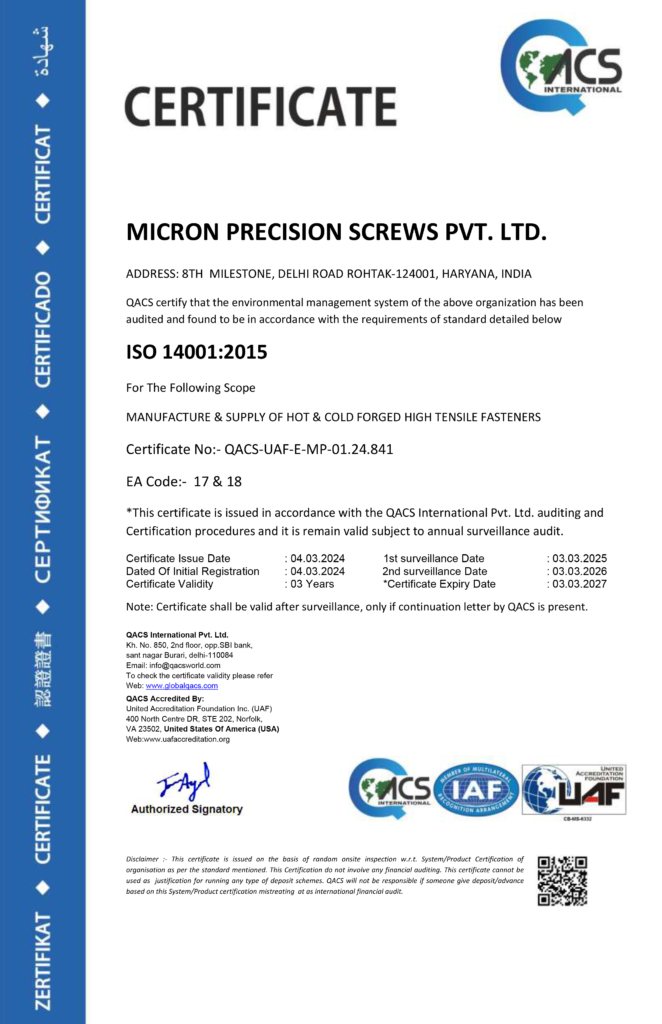

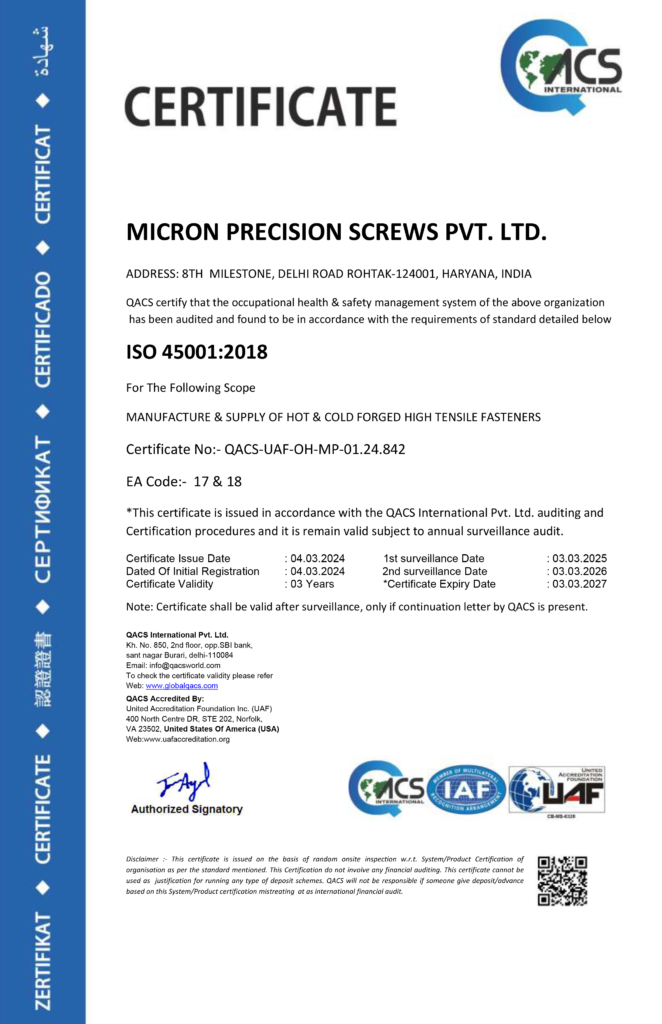

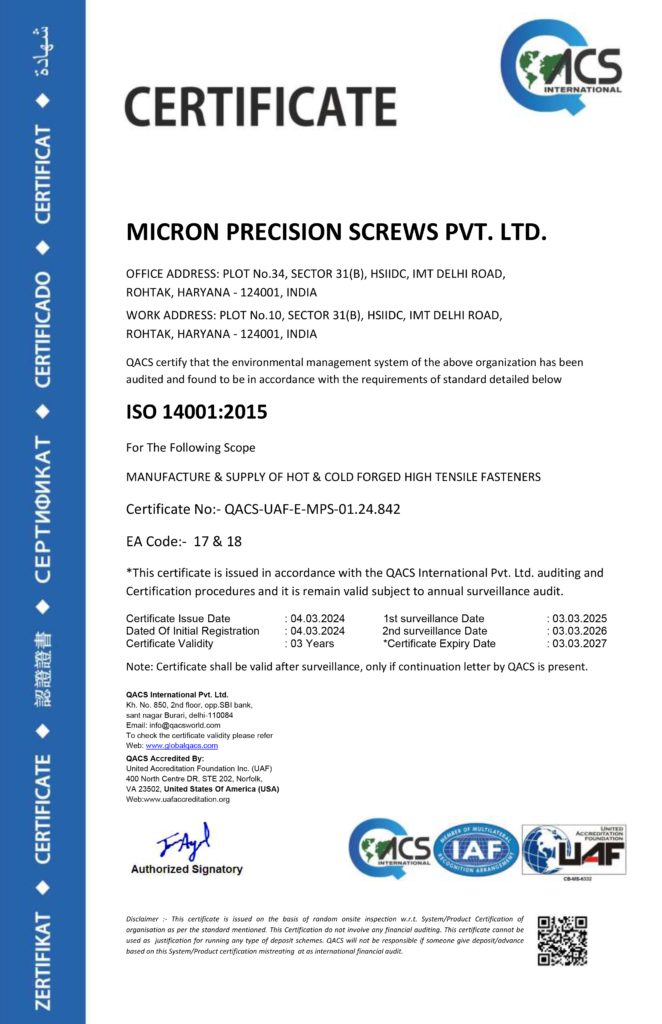

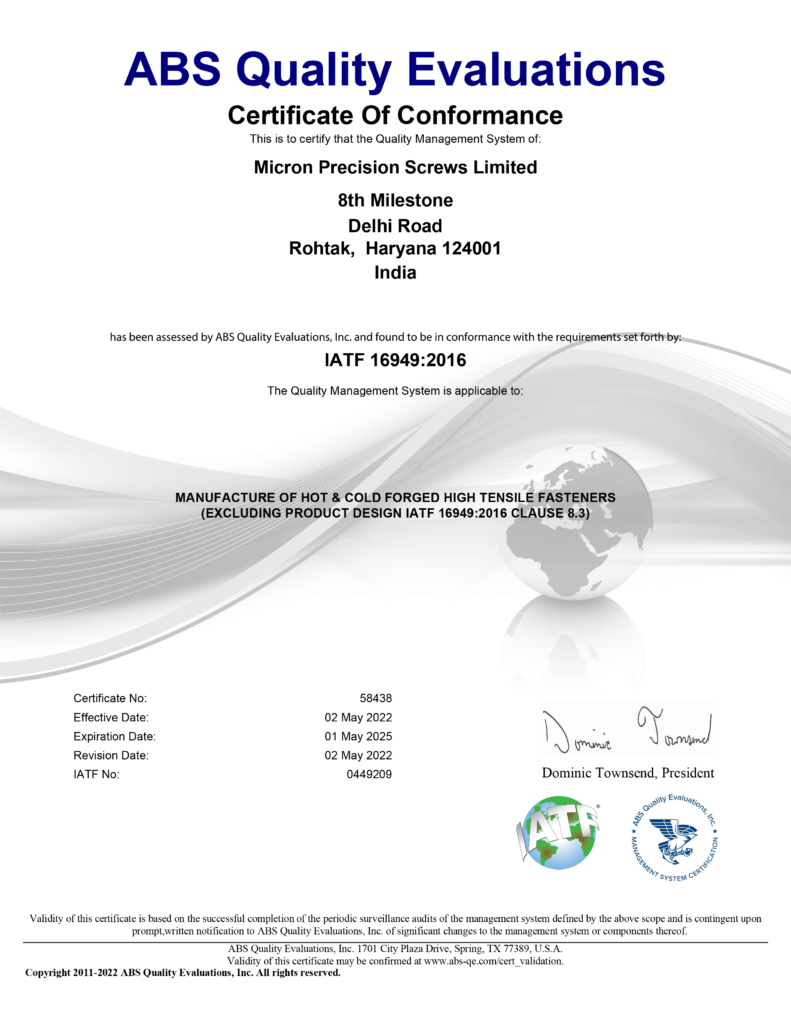

Quality certificates & Testing Equipment

We strive to provide quality products by adhering to National and International Quality Standards e.g. DIN, BS, IS, ANSI and so on. We ensure effective implementation of ISO 9001: 2015 in the fastener manufacturing plants.